The volleyball industry represents a multi-billion dollar global market where importers play a crucial role in connecting manufacturers with retailers and end consumers. When engaging in the process of buying volleyball equipment, importers must navigate complex considerations that extend far beyond simple price comparisons. Understanding these factors can mean the difference between a profitable venture and costly mistakes that impact both immediate returns and long-term business relationships. The decision-making process involves evaluating quality standards, regulatory compliance, supplier reliability, and market positioning strategies that align with target demographics and regional preferences.

Quality Standards and Material Specifications

Construction Materials and Durability Assessment

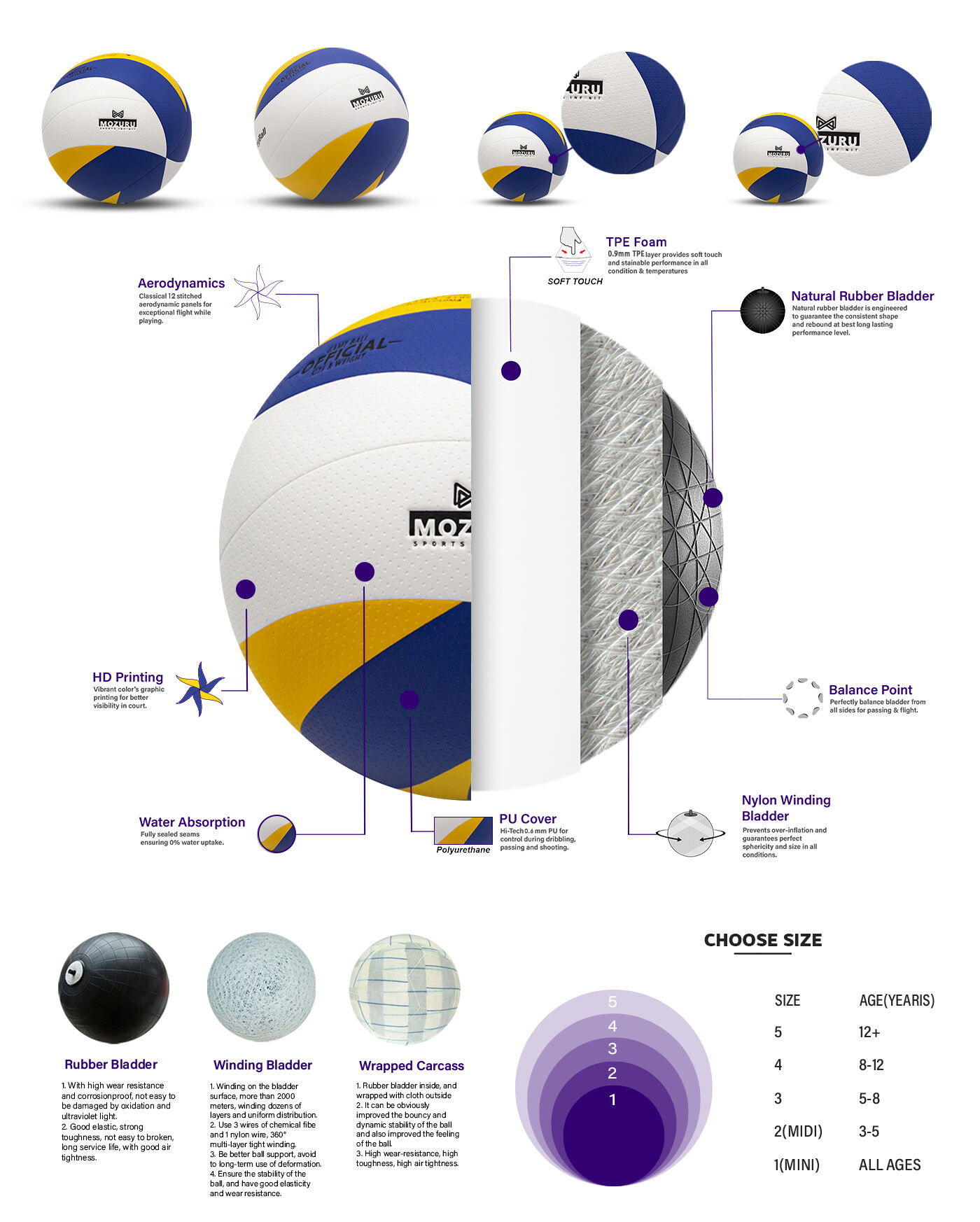

Professional volleyball construction requires specific material compositions that directly impact performance and longevity. Synthetic leather remains the preferred choice for competitive play due to its consistent texture and moisture resistance properties. When evaluating suppliers, importers should examine the quality of synthetic materials, stitching techniques, and bladder construction. High-quality volleyballs typically feature 18-panel construction with precision-molded synthetic leather that maintains shape integrity under varying temperature conditions. The internal bladder material, usually butyl or natural rubber, significantly affects air retention and bounce consistency over extended periods.

Durability testing protocols should include assessments of panel separation resistance, color retention under UV exposure, and compression recovery after repeated impacts. Professional-grade volleyballs undergo rigorous testing that simulates thousands of plays to ensure consistent performance throughout their lifespan. Importers must request detailed specifications regarding material sourcing, manufacturing processes, and quality control measures implemented by potential suppliers. Understanding these technical aspects enables informed decisions when buying volleyball inventory for different market segments.

Performance Standards and Certification Requirements

International volleyball federations establish specific performance criteria that govern official competition equipment. The Federation Internationale de Volleyball sets standards for circumference measurements, weight specifications, and pressure requirements that manufacturers must meet for official approval. These standards ensure consistent playing conditions across different venues and competitions worldwide. Importers should verify that their suppliers maintain current certifications and understand the implications of selling non-certified equipment in various markets.

Performance testing encompasses ball trajectory consistency, rebound characteristics, and grip surface properties under different environmental conditions. Professional testing facilities evaluate these parameters using standardized equipment and protocols that measure deviation from established norms. Importers benefit from requesting performance test reports and understanding how different material choices impact playing characteristics. This knowledge enables better matching of product specifications to target market requirements and helps establish appropriate pricing strategies for different quality tiers.

Supplier Evaluation and Manufacturing Capabilities

Production Capacity and Scalability Assessment

Manufacturing capacity analysis involves examining both current production volumes and scalability potential to meet future demand fluctuations. Established volleyball manufacturers typically operate facilities capable of producing thousands of units daily while maintaining consistent quality standards. Importers should evaluate production line efficiency, equipment modernization levels, and workforce training programs that contribute to overall manufacturing capabilities. Understanding seasonal demand patterns in target markets helps determine whether supplier capacity aligns with projected order volumes.

Scalability considerations include the supplier's ability to accommodate rush orders, customize products for specific markets, and maintain quality consistency during production increases. Modern manufacturing facilities incorporate automated cutting systems, precision stitching equipment, and computerized quality control processes that enable rapid scaling without compromising standards. Importers should assess supplier flexibility in handling varying order sizes and their track record of meeting delivery commitments during peak demand periods.

Quality Control Systems and Compliance Protocols

Comprehensive quality control systems encompass raw material inspection, in-process monitoring, and final product testing before shipment. Effective suppliers implement multi-stage quality checkpoints that identify and address potential issues before they impact finished products. These systems typically include dimensional verification, weight consistency checks, pressure testing, and visual inspection protocols performed by trained personnel using calibrated equipment. Documentation of quality control procedures provides importers with confidence in supplier reliability and helps establish accountability for product standards.

Compliance protocols extend beyond product quality to include environmental standards, labor practices, and safety regulations governing manufacturing operations. Reputable suppliers maintain certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and relevant social compliance audits that demonstrate commitment to ethical business practices. Importers should verify these certifications and understand their implications for long-term business relationships and market acceptance in regions with strict compliance requirements.

Market Analysis and Target Segment Identification

Consumer Demographics and Preference Mapping

Successful volleyball importing requires thorough understanding of target market demographics and their specific preferences regarding product features, pricing, and performance characteristics. Different regions exhibit varying preferences for ball weight, texture, and color schemes based on local playing traditions and climate conditions. Youth markets typically prioritize softer touch and lighter weight specifications, while competitive adult segments demand firmer construction and precise performance characteristics. Understanding these nuances enables importers to select appropriate product mixes and avoid inventory challenges related to mismatched specifications.

Market research should encompass recreational versus competitive usage patterns, indoor versus outdoor playing preferences, and seasonal demand variations that influence purchasing timing. Beach volleyball segments require different material specifications compared to indoor court applications, including enhanced UV resistance and sand-resistant surface treatments. Demographic analysis helps identify growth opportunities and potential challenges in different market segments, enabling strategic positioning and targeted marketing approaches.

Competitive Landscape and Positioning Strategy

The volleyball equipment market features established international brands alongside emerging manufacturers competing across various price points and quality levels. Competitive analysis should examine brand positioning, pricing strategies, distribution channels, and marketing approaches used by existing market participants. Understanding competitive dynamics helps importers identify market gaps and develop differentiation strategies that leverage supplier capabilities and market opportunities.

Positioning strategy development involves balancing quality perceptions with price sensitivity across different market segments. Premium positioning requires superior materials and manufacturing processes that justify higher retail prices, while value positioning emphasizes cost-effectiveness without compromising essential performance characteristics. Importers must align supplier capabilities with intended market positioning and ensure that product specifications support chosen competitive strategies throughout the distribution chain.

Regulatory Compliance and Import Considerations

International Standards and Certification Requirements

International trade in volleyball equipment involves compliance with various safety standards, labeling requirements, and import regulations that vary significantly between countries and regions. The United States requires compliance with Consumer Product Safety Commission regulations, while European markets mandate CE marking and conformity with relevant EN standards. Understanding these requirements prevents costly delays and ensures smooth customs clearance processes. Importers should verify that suppliers maintain current certifications and provide necessary documentation for compliance verification.

Product testing and certification processes often require significant lead times and coordination between suppliers and accredited testing facilities. Planning for these requirements during supplier evaluation helps prevent delays in product launches and ensures adequate inventory availability. Documentation requirements include material safety data sheets, test reports, and declaration of conformity statements that customs authorities may request during import processing.

Tariff Classifications and Trade Considerations

Proper tariff classification significantly impacts import costs and overall profitability when buying volleyball equipment from international suppliers. Volleyball equipment typically falls under specific Harmonized System codes that determine applicable duty rates and any preferential trade agreement benefits. Understanding these classifications and their implications helps importers calculate accurate landed costs and develop competitive pricing strategies for different markets.

Trade agreement benefits, such as those available under various free trade agreements, can substantially reduce import duties and improve competitive positioning. Importers should evaluate supplier locations in relation to available trade preferences and consider how these factors influence total cost calculations. Currency fluctuation impacts also require consideration when establishing long-term supplier relationships and pricing commitments that extend across multiple ordering cycles.

Logistics and Supply Chain Management

Shipping Methods and Lead Time Optimization

Effective logistics planning encompasses shipping method selection, container optimization, and lead time management that balances cost efficiency with inventory requirements. Ocean freight remains the most cost-effective option for large volume shipments, while air freight provides faster delivery for urgent orders or seasonal inventory replenishment. Understanding the trade-offs between shipping costs and inventory carrying costs helps optimize overall supply chain expenses and customer service levels.

Container loading optimization involves calculating optimal packaging configurations that maximize space utilization while protecting products during transit. Volleyball packaging typically allows for efficient stacking and nesting arrangements that minimize wasted space and reduce per-unit shipping costs. Coordination with suppliers on packaging design and loading procedures can significantly impact overall logistics efficiency and cost structures.

Inventory Management and Demand Forecasting

Accurate demand forecasting requires analysis of historical sales patterns, seasonal variations, and market growth trends that influence volleyball equipment consumption. School year calendars, tournament schedules, and recreational facility programming create predictable demand patterns that importers can leverage for inventory planning. Understanding these cycles enables optimal ordering timing and inventory level management that minimizes stockouts while avoiding excessive carrying costs.

Inventory turnover optimization involves balancing product variety with volume concentrations to achieve efficient working capital utilization. Fast-moving core products should receive priority in inventory allocation, while specialty items require careful demand assessment to prevent slow-moving inventory accumulation. Effective inventory management systems provide visibility into stock levels, turnover rates, and reorder points that support proactive supply chain management decisions.

Financial Considerations and Risk Management

Cost Structure Analysis and Pricing Strategy

Comprehensive cost analysis encompasses product costs, shipping expenses, import duties, handling fees, and working capital requirements that contribute to total landed costs. Understanding these components enables accurate pricing calculations and margin analysis that support sustainable business operations. Hidden costs, such as quality inspection fees, storage charges, and insurance premiums, should be incorporated into total cost calculations to ensure profitability targets are achievable.

Pricing strategy development requires consideration of competitive positioning, market acceptance levels, and distribution channel margins that influence final retail prices. Value-based pricing approaches focus on perceived benefits and performance characteristics, while cost-plus pricing ensures adequate margins across different product lines. Understanding customer price sensitivity and competitive responses helps establish optimal pricing strategies that maximize revenue while maintaining market competitiveness.

Payment Terms and Currency Risk Management

International supplier relationships involve payment term negotiations that balance cash flow requirements with supplier preferences and industry standards. Letter of credit arrangements provide security for both parties but involve additional costs and processing complexity. Payment timing affects working capital requirements and should align with cash flow patterns and seasonal demand cycles that characterize volleyball equipment markets.

Currency risk management becomes critical when dealing with suppliers operating in different currencies and markets with volatile exchange rates. Forward contracts, currency hedging strategies, and payment timing optimization can help minimize adverse currency movements that erode profit margins. Long-term supplier relationships benefit from establishing currency risk management protocols that provide predictability for both parties while maintaining competitive cost structures.

FAQ

What quality certifications should importers look for when buying volleyball equipment

Importers should prioritize suppliers with ISO 9001 quality management certification, relevant sports equipment standards compliance, and federation approvals from organizations like FIVB. Additional certifications such as BSCI for social compliance and ISO 14001 for environmental management indicate comprehensive operational standards. Product-specific certifications vary by target market but typically include safety testing reports and material compliance documentation required by destination country regulations.

How do seasonal demand patterns affect volleyball importing strategies

Volleyball equipment demand typically peaks during back-to-school periods and spring recreational seasons, requiring advance planning and inventory accumulation. School and university purchasing cycles drive significant volume requirements in late summer and early fall, while recreational demand increases during warmer months when outdoor activities expand. Understanding these patterns enables optimal ordering timing, inventory management, and cash flow planning that maximizes sales opportunities while minimizing carrying costs.

What are the key differences between indoor and outdoor volleyball specifications

Indoor volleyballs feature softer synthetic leather construction optimized for controlled environments and precise handling characteristics required for competitive play. Outdoor volleyballs require enhanced UV resistance, water-resistant treatments, and more durable surface materials to withstand weather exposure and varied playing surfaces. Weight and pressure specifications may also differ slightly to account for temperature variations and different playing conditions encountered in outdoor environments.

How can importers evaluate supplier reliability and manufacturing consistency

Supplier evaluation should include facility visits, quality system audits, and reference checks with existing customers to assess manufacturing capabilities and reliability track records. Production capacity verification, quality control system assessment, and delivery performance history provide insights into operational consistency and scalability potential. Financial stability analysis and compliance certification verification help ensure long-term partnership viability and minimize supply chain disruption risks.

Table of Contents

- Quality Standards and Material Specifications

- Supplier Evaluation and Manufacturing Capabilities

- Market Analysis and Target Segment Identification

- Regulatory Compliance and Import Considerations

- Logistics and Supply Chain Management

- Financial Considerations and Risk Management

-

FAQ

- What quality certifications should importers look for when buying volleyball equipment

- How do seasonal demand patterns affect volleyball importing strategies

- What are the key differences between indoor and outdoor volleyball specifications

- How can importers evaluate supplier reliability and manufacturing consistency