Sourcing high-quality baseball gloves in bulk requires strategic planning, thorough supplier evaluation, and careful attention to manufacturing standards. Importers who understand the complexities of bulk procurement can secure competitive pricing while maintaining product quality that meets market demands. The baseball equipment industry continues to grow, with recreational and professional leagues driving consistent demand for reliable protective gear. Successful importers recognize that establishing strong supplier relationships and implementing quality control measures are essential for long-term profitability in this competitive market.

Understanding Market Requirements for Baseball Glove Procurement

Identifying Target Demographics and Quality Standards

Professional importers must thoroughly analyze their target market before initiating bulk purchasing decisions. Youth leagues typically require affordable yet durable options, while high school and college teams demand enhanced performance features and superior construction quality. Adult recreational leagues often seek mid-range products that balance cost-effectiveness with reliable functionality. Understanding these distinct market segments enables importers to select appropriate product specifications and negotiate favorable terms with manufacturers.

Quality standards vary significantly across different market tiers, requiring importers to establish clear specifications for materials, construction methods, and performance characteristics. Premium segments expect full-grain leather construction, reinforced stitching, and ergonomic design features that enhance player comfort and performance. Budget-conscious segments may accept synthetic materials and simplified construction techniques, provided the products maintain acceptable durability levels. Establishing these parameters early in the sourcing process helps streamline supplier selection and quality control procedures.

Analyzing Seasonal Demand Patterns and Inventory Planning

Baseball equipment sales follow predictable seasonal patterns that significantly impact bulk procurement strategies. Spring season preparations drive peak demand periods, typically beginning in late winter and extending through early summer months. Importers must coordinate their sourcing timelines to ensure adequate inventory levels during these critical sales periods while avoiding excessive carrying costs during slower months. Effective demand forecasting requires analysis of historical sales data, regional climate patterns, and local league scheduling variations.

Inventory planning for baseball gloves in bulk involves balancing size distributions, position-specific requirements, and quality tiers to meet diverse customer needs. Catchers' mitts, first basemen's gloves, and standard fielding gloves require different inventory allocation strategies based on their respective usage rates. Importers who maintain detailed sales analytics can optimize their procurement volumes and reduce excess inventory risks while ensuring availability of popular size and style combinations throughout the selling season.

Supplier Evaluation and Selection Criteria

Assessing Manufacturing Capabilities and Production Capacity

Thorough evaluation of potential suppliers involves examining their manufacturing facilities, production equipment, and quality control systems. Established manufacturers typically possess specialized machinery for leather cutting, stitching, and forming processes that ensure consistent product quality across large production runs. Importers should conduct facility inspections or request detailed documentation of manufacturing capabilities, including production capacity, lead times, and scalability options for future growth requirements.

Production capacity assessment involves understanding both current output levels and potential expansion capabilities during peak demand periods. Reliable suppliers maintain adequate raw material inventories, skilled workforce availability, and backup equipment to handle unexpected order increases or production disruptions. Importers benefit from partnering with manufacturers who demonstrate flexibility in accommodating varying order sizes and delivery schedules while maintaining consistent quality standards throughout different production volumes.

Verifying Certifications and Compliance Standards

International trade regulations and safety standards require suppliers to maintain appropriate certifications and compliance documentation. Reputable manufacturers typically hold ISO quality management certifications, environmental compliance certificates, and product safety testing documentation that meets importing country requirements. Importers must verify these credentials and ensure suppliers maintain current certifications throughout the business relationship to avoid potential customs delays or regulatory complications.

Product testing and certification requirements vary by destination market, necessitating careful coordination between importers and suppliers regarding compliance obligations. Some markets require specific chemical testing for leather treatments, while others mandate particular labeling or packaging standards for sporting goods. Suppliers who understand these requirements and maintain appropriate testing capabilities can significantly streamline the import process and reduce compliance-related risks for their international customers.

Quality Control and Product Specifications

Establishing Material Standards and Construction Requirements

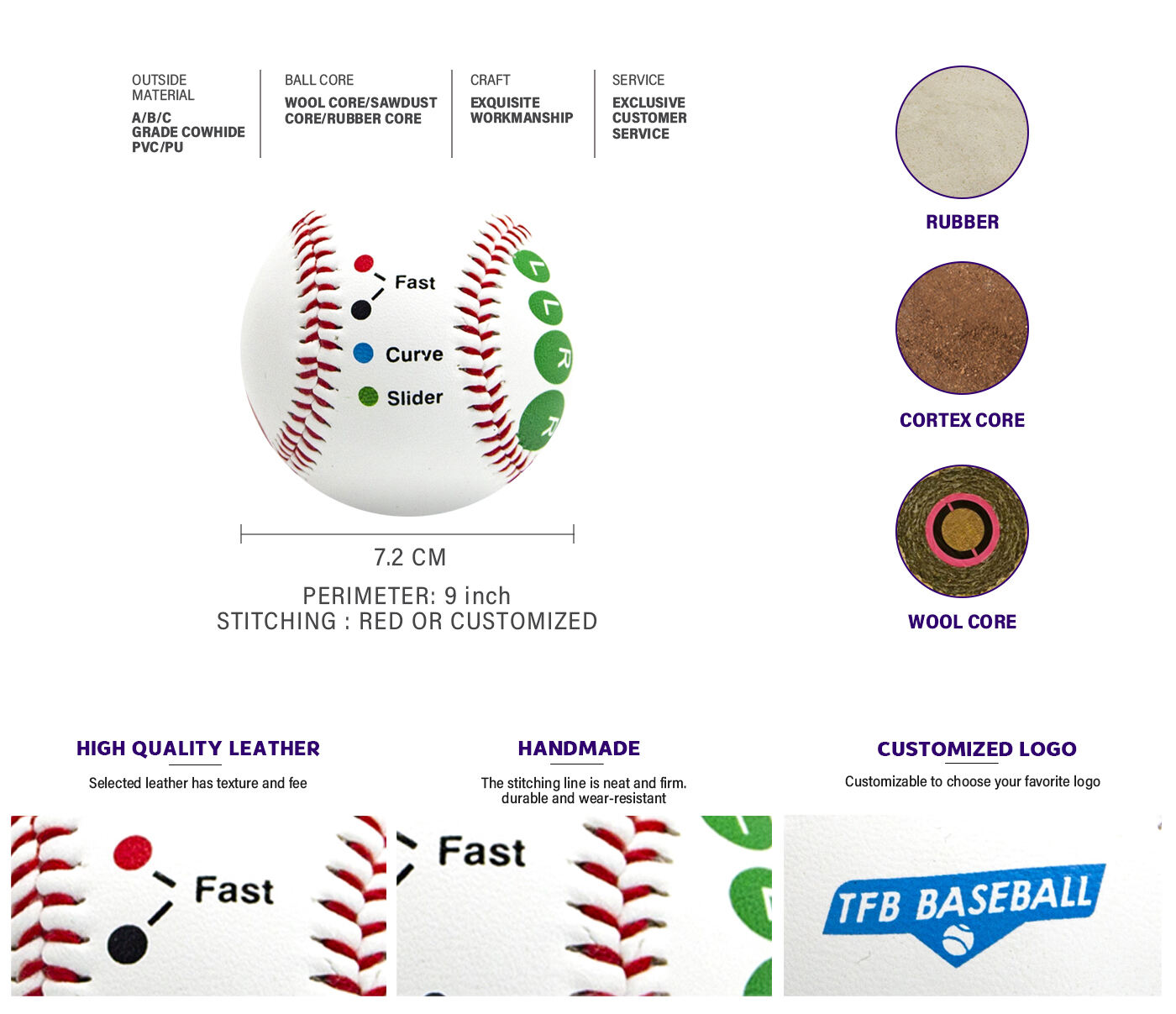

Successful bulk procurement requires detailed specifications covering leather quality grades, stitching techniques, and hardware components used in glove construction. Premium leather selections should specify full-grain or top-grain materials with appropriate thickness measurements and flexibility characteristics. Synthetic alternatives must meet durability standards while providing adequate grip and comfort features. Clear material specifications prevent quality variations and ensure consistent product performance across entire order quantities.

Construction requirements encompass stitching patterns, reinforcement techniques, and assembly methods that impact product durability and performance characteristics. Double-stitched seams, reinforced stress points, and quality lacing systems contribute to extended product lifespan and enhanced user satisfaction. Importers should establish minimum construction standards and implement inspection procedures to verify compliance with these specifications throughout the manufacturing process.

Implementing Inspection Protocols and Testing Procedures

Comprehensive quality control programs incorporate pre-production sampling, in-process monitoring, and final inspection procedures that identify potential issues before shipment completion. Pre-production samples allow importers to verify material quality, construction techniques, and dimensional accuracy before full production begins. This approach prevents costly corrections and ensures final products meet established specifications from the initial production run.

Final inspection procedures should include random sampling protocols, durability testing, and visual quality assessments that verify conformance to agreed specifications. Testing procedures may involve stress testing of stitching, flexibility measurements, and dimensional verification to ensure consistency across the entire production batch. Documented inspection results provide valuable feedback for continuous improvement and help maintain quality standards throughout ongoing supplier relationships.

Pricing Strategies and Negotiation Techniques

Understanding Cost Structure and Market Pricing

Effective negotiation requires comprehensive understanding of manufacturing cost components including raw materials, labor, overhead expenses, and profit margins. Material costs typically represent the largest expense category, with leather prices fluctuating based on market conditions and quality grades. Labor costs vary significantly between manufacturing regions, while overhead expenses include facility costs, equipment depreciation, and administrative expenses that impact final pricing structures.

Market pricing analysis involves comparing multiple supplier quotations while considering total landed costs including shipping, insurance, customs duties, and handling fees. The lowest initial price may not represent the best value when transportation costs, delivery reliability, and quality consistency factors are included in the evaluation process. Importers who develop comprehensive cost analysis models can make more informed supplier selection decisions and negotiate more effectively with potential partners.

Leveraging Volume Commitments and Payment Terms

Volume commitments provide significant leverage in price negotiations, with larger order quantities typically yielding better per-unit pricing and improved payment terms. Suppliers often offer tiered pricing structures that reward increased volume commitments with progressively better rates. Long-term contracts with minimum volume guarantees can secure favorable pricing while providing suppliers with production planning certainty that benefits both parties in the business relationship.

Payment term negotiations should balance cash flow considerations with available discounts for early payment or larger deposits. Many suppliers offer percentage discounts for advance payments or shorter payment cycles, which can significantly impact overall procurement costs. However, importers must carefully evaluate their cash flow capabilities and risk tolerance when committing to accelerated payment schedules, particularly with new or unproven supplier relationships.

Logistics and Import Management

Coordinating Shipping Methods and Documentation Requirements

Efficient logistics management involves selecting appropriate shipping methods that balance cost considerations with delivery timeline requirements. Ocean freight typically provides the most cost-effective solution for large bulk orders, while air freight may be necessary for urgent replenishment or seasonal deadline requirements. Container optimization strategies can significantly reduce per-unit shipping costs by maximizing cargo density and minimizing wasted space during transportation.

Documentation requirements include commercial invoices, packing lists, bills of lading, and any special certificates required by importing country regulations. Accurate documentation prevents customs delays and ensures smooth clearance procedures upon arrival. Importers should establish clear communication protocols with suppliers regarding documentation preparation and submission timelines to avoid last-minute complications that could impact delivery schedules.

Managing Customs Clearance and Duty Optimization

Customs clearance procedures require careful attention to product classification, duty rates, and any applicable trade agreements that may provide preferential treatment. Proper classification under the Harmonized Tariff Schedule ensures accurate duty calculations and compliance with import regulations. Some trade agreements offer reduced duty rates or duty-free treatment for qualifying products, potentially providing significant cost savings for eligible importers.

Duty optimization strategies may include exploring different manufacturing origins, utilizing free trade zone facilities, or timing shipments to coincide with favorable regulatory changes. Professional customs brokers can provide valuable guidance regarding compliance requirements and optimization opportunities. Their expertise helps navigate complex regulations while ensuring full compliance with all applicable import requirements and documentation procedures.

Building Long-Term Supplier Relationships

Establishing Communication Protocols and Performance Metrics

Successful long-term partnerships require clear communication channels and regular performance evaluations that maintain quality standards while fostering continuous improvement. Regular communication schedules should include production updates, quality reports, and market feedback that helps suppliers understand customer requirements and market trends. Establishing these protocols early in the relationship prevents misunderstandings and ensures both parties maintain aligned expectations throughout the business partnership.

Performance metrics should encompass quality consistency, delivery reliability, responsiveness to issues, and competitive pricing maintenance over time. Quantifiable measurements provide objective evaluation criteria and help identify areas for improvement or recognition. Suppliers who consistently meet or exceed established performance standards deserve recognition and preferential treatment that encourages continued excellence and strengthens the business relationship.

Developing Mutual Growth Opportunities and Innovation

Strategic partnerships extend beyond basic procurement relationships to include collaborative product development, market expansion opportunities, and shared innovation initiatives. Suppliers with strong research and development capabilities can contribute valuable insights regarding new materials, construction techniques, or design features that enhance product competitiveness. These collaborative efforts often result in exclusive product offerings or improved manufacturing processes that benefit both parties.

Market expansion opportunities may include developing products for new customer segments, exploring different geographic markets, or adapting existing designs for specialized applications. When sourcing baseball gloves in bulk, importers who maintain open communication about market opportunities can work with suppliers to develop customized solutions that meet specific customer requirements while maintaining cost-effectiveness and quality standards.

FAQ

What minimum order quantities should importers expect when sourcing baseball gloves in bulk?

Most manufacturers require minimum order quantities ranging from 500 to 2,000 pieces depending on customization requirements and product complexity. Standard designs typically have lower minimums, while custom colors, logos, or specifications may require larger initial orders. Importers should discuss quantity flexibility during negotiations, as some suppliers offer mixed size assortments or seasonal ordering programs that accommodate smaller initial commitments while building toward larger volume relationships.

How long does the typical production and shipping process take for bulk baseball glove orders?

Production lead times generally range from 30 to 60 days depending on order complexity, seasonal demand, and supplier capacity. Custom specifications, special materials, or unique design requirements may extend production timelines to 90 days or longer. Ocean shipping adds approximately 2-4 weeks for most international routes, while customs clearance typically requires 3-7 days. Importers should plan for total procurement cycles of 8-12 weeks to ensure adequate inventory availability for peak selling seasons.

What quality certifications should importers require from baseball glove manufacturers?

Reputable manufacturers should maintain ISO 9001 quality management certification, product safety testing documentation, and environmental compliance certificates. Specific testing may include chemical analysis of leather treatments, durability testing reports, and dimensional verification documentation. Import markets may require additional certifications such as CPSIA compliance for youth products in the United States or CE marking for European markets. Importers should verify all required certifications before finalizing supplier agreements to prevent compliance issues.

How can importers effectively manage quality control across large bulk orders?

Effective quality control requires establishing clear specifications, implementing staged inspection procedures, and maintaining open communication with suppliers throughout production. Pre-production sampling ensures materials and construction meet requirements before full production begins. In-process inspections at 25%, 50%, and 90% completion stages identify issues early and prevent widespread problems. Final random sampling of 5-10% of finished goods provides confidence in overall batch quality while remaining cost-effective for large order quantities.

Table of Contents

- Understanding Market Requirements for Baseball Glove Procurement

- Supplier Evaluation and Selection Criteria

- Quality Control and Product Specifications

- Pricing Strategies and Negotiation Techniques

- Logistics and Import Management

- Building Long-Term Supplier Relationships

-

FAQ

- What minimum order quantities should importers expect when sourcing baseball gloves in bulk?

- How long does the typical production and shipping process take for bulk baseball glove orders?

- What quality certifications should importers require from baseball glove manufacturers?

- How can importers effectively manage quality control across large bulk orders?