When organizations, schools, or recreational facilities need to procure large quantities of sporting equipment, making informed decisions about bulk baseball purchase becomes crucial for both budget management and performance outcomes. The process involves evaluating multiple factors that can significantly impact the overall value and satisfaction of your investment. Understanding these key considerations will help buyers navigate the complex landscape of wholesale sporting goods procurement while ensuring they receive quality products that meet their specific operational requirements.

The sporting goods industry has evolved dramatically over the past decade, with manufacturers offering increasingly sophisticated options for institutional buyers. Modern procurement strategies must account for technological advances in ball construction, regulatory compliance requirements, and the diverse needs of different user groups. Whether you're outfitting a professional training facility, educational institution, or community recreation center, the decisions you make during the purchasing process will have lasting implications for player safety, performance standards, and operational efficiency.

Quality Assessment and Material Standards

Core Construction Materials

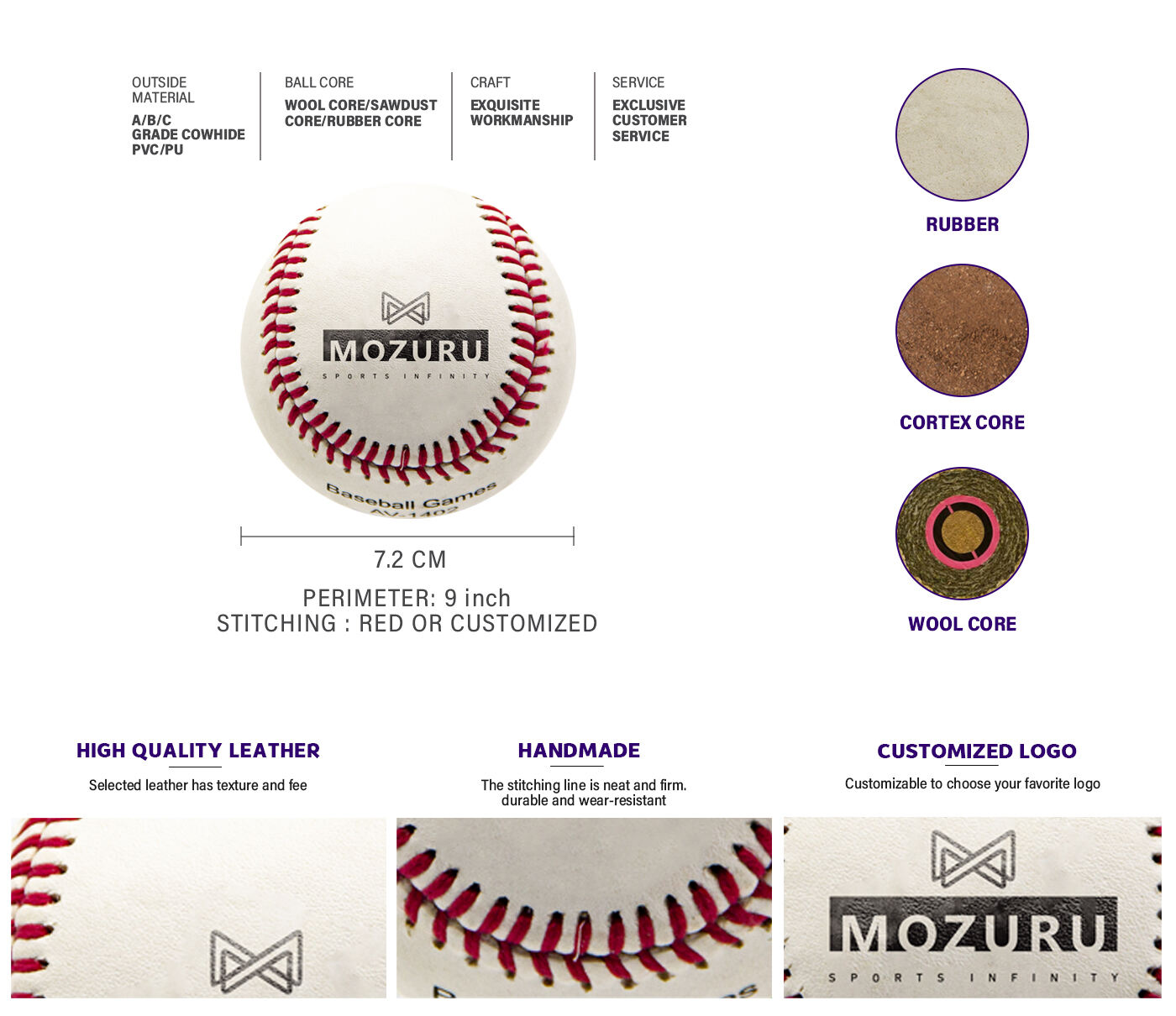

The foundation of any quality baseball lies in its core construction, which directly influences durability, performance consistency, and longevity under regular use. Professional-grade balls typically feature cork and rubber centers wrapped in multiple layers of yarn, while recreational options may utilize synthetic alternatives that offer adequate performance at reduced costs. When evaluating options for bulk baseball purchase, buyers should request detailed specifications regarding core density, compression ratings, and material composition to ensure alignment with intended usage patterns.

Modern manufacturing techniques have introduced various core technologies that affect ball behavior and lifespan. Cushioned cork centers provide superior resilience and maintain consistent performance characteristics over extended periods, making them ideal for competitive environments. Alternatively, synthetic rubber cores offer enhanced durability for high-volume recreational use where consistent replacement schedules may be more challenging to maintain. Understanding these material differences enables informed decision-making based on specific operational requirements and budget constraints.

Cover Quality and Durability

The exterior covering represents the most visible aspect of baseball quality and directly impacts grip, aerodynamics, and overall player experience. Genuine leather covers remain the gold standard for professional applications, offering superior tactile feedback, weather resistance, and aesthetic appeal. However, synthetic leather alternatives have achieved remarkable quality improvements while providing cost advantages that make them attractive for educational and recreational bulk purchases.

Stitching quality deserves particular attention during the evaluation process, as inadequate seam construction can lead to premature failure and safety concerns. Hand-stitched balls typically offer superior durability compared to machine-stitched alternatives, though advances in automated manufacturing have narrowed this gap considerably. Buyers should examine stitch density, thread quality, and seam consistency when assessing potential suppliers for their bulk baseball purchase requirements.

Regulatory Compliance and Certification Standards

Official League Specifications

Different sporting organizations maintain specific equipment standards that must be considered during the procurement process. Major League Baseball, NCAA, NFHS, and various youth leagues each have detailed specifications regarding ball weight, circumference, coefficient of restitution, and construction materials. Ensuring compliance with relevant regulatory standards is essential for organizations that participate in sanctioned competitions or wish to maintain consistency with established playing conditions.

Certification processes vary significantly between governing bodies, with some requiring extensive testing and documentation while others rely on manufacturer self-certification. Buyers should verify that their selected products carry appropriate certifications for their intended applications and understand any limitations or restrictions associated with specific approvals. This due diligence becomes particularly important for educational institutions that may participate in multiple leagues with varying equipment requirements.

Safety and Performance Testing

Independent testing laboratories provide valuable verification of manufacturer claims regarding ball performance and safety characteristics. NOCSAE (National Operating Committee on Standards for Athletic Equipment) certification represents the most rigorous safety standard for baseball equipment, though not all applications require this level of verification. Understanding the testing protocols and certification levels appropriate for your specific use case helps ensure both regulatory compliance and participant safety.

Performance testing encompasses various metrics including coefficient of restitution, compression resistance, durability under repeated impact, and dimensional stability across temperature ranges. Reputable suppliers should provide comprehensive testing documentation and be prepared to discuss how their products perform under real-world conditions. This information becomes crucial when making bulk baseball purchase decisions that will affect large numbers of players over extended periods.

Supplier Evaluation and Procurement Strategy

Vendor Assessment Criteria

Selecting the right supplier involves evaluating multiple factors beyond initial pricing, including manufacturing capability, quality control processes, delivery reliability, and customer service responsiveness. Established suppliers typically offer better consistency and support, though newer companies may provide competitive pricing or innovative product features. Conducting thorough vendor assessments helps mitigate risks associated with large-volume purchases and ensures long-term satisfaction with the procurement decision.

Supply chain stability has become increasingly important following recent global disruptions that affected manufacturing and logistics operations worldwide. Vendors with diversified production facilities, robust inventory management systems, and established relationships with transportation providers offer greater reliability for time-sensitive deliveries. Evaluating supplier financial stability, manufacturing capacity, and contingency planning capabilities provides insight into their ability to fulfill large orders consistently.

Contract Terms and Service Agreements

Negotiating favorable contract terms becomes crucial for bulk purchases, particularly regarding warranty coverage, replacement policies, and delivery schedules. Many suppliers offer tiered pricing structures based on volume commitments, seasonal ordering patterns, or multi-year agreements that can provide significant cost savings. Understanding these options and structuring agreements to maximize value while minimizing risk requires careful analysis of usage patterns and budget constraints.

Service level agreements should address quality standards, delivery timeframes, packaging requirements, and procedures for handling defective products. Clear communication protocols and escalation procedures help resolve issues quickly when they arise, minimizing disruptions to operations. Establishing these parameters upfront prevents misunderstandings and ensures both parties understand their responsibilities throughout the relationship.

Cost Analysis and Budget Planning

Total Cost of Ownership

Effective budget planning for bulk baseball purchase requires consideration of total cost of ownership rather than simply initial acquisition costs. This comprehensive approach includes product pricing, shipping expenses, storage requirements, handling costs, and expected replacement schedules. Higher-quality balls may command premium prices but offer superior durability that reduces overall costs over time through extended service life and reduced replacement frequency.

Hidden costs can significantly impact budget projections, including customs duties for imported products, special handling requirements for fragile items, and storage facility modifications needed to accommodate large shipments. Conducting thorough cost analysis helps prevent budget overruns and enables more accurate financial planning for ongoing operations. This analysis becomes particularly important for organizations with limited storage capacity or complex logistics requirements.

Volume Pricing and Negotiation Strategies

Bulk purchasing typically offers substantial cost savings through volume discounts, though the optimal order quantity depends on usage rates, storage capacity, and cash flow considerations. Suppliers often provide tiered pricing structures that reward larger commitments, but buyers must balance potential savings against carrying costs and risk of obsolescence. Analyzing historical usage patterns and projecting future needs helps determine the most cost-effective order quantities.

Negotiation strategies should focus on achieving the best overall value rather than simply the lowest unit price. Factors such as payment terms, delivery flexibility, warranty coverage, and additional services can provide significant value that justifies slightly higher pricing. Building long-term relationships with reliable suppliers often yields better pricing and service over time compared to constantly switching vendors based solely on initial quotes.

Storage and Inventory Management

Proper Storage Conditions

Maintaining product quality during storage requires appropriate environmental controls and handling procedures. Baseballs are sensitive to temperature extremes, humidity variations, and direct sunlight exposure, all of which can affect performance characteristics and longevity. Establishing proper storage protocols protects your investment and ensures consistent product quality throughout the usage period.

Climate-controlled storage facilities provide optimal conditions for long-term ball preservation, though such facilities may not be available or cost-effective for all organizations. Alternative approaches include protective packaging, rotation schedules, and environmental monitoring to minimize deterioration. Understanding the storage requirements for different ball types helps optimize facility utilization and prevent premature product degradation.

Inventory Tracking and Distribution

Effective inventory management systems enable efficient distribution while maintaining accurate records of usage patterns and replacement needs. Modern tracking systems can provide valuable insights into consumption rates, seasonal variations, and equipment lifecycle patterns that inform future purchasing decisions. Implementing systematic approaches to inventory management reduces waste and ensures adequate supplies are always available.

Distribution protocols should account for different quality requirements across various programs or user groups within an organization. Competition-level activities may require premium products while practice sessions can utilize more economical alternatives. Developing clear allocation guidelines ensures appropriate products are used for their intended purposes while maximizing overall value from the bulk baseball purchase investment.

FAQ

What quantity constitutes a bulk purchase for baseballs

Bulk purchasing typically begins at quantities of 100-200 baseballs, though volume discounts become more significant at quantities exceeding 500-1000 units. Educational institutions and recreational facilities commonly order between 1000-5000 baseballs annually, while professional organizations may require tens of thousands. The specific threshold for bulk pricing varies by supplier, but most manufacturers offer tiered discounts starting around 500 units with additional savings at higher volumes.

How should organizations determine the appropriate quality level for their needs

Quality selection should align with intended usage patterns and performance requirements. Professional competitions require official league-certified balls with premium construction, while recreational activities can utilize more economical alternatives without compromising safety or basic performance. Consider factors such as frequency of use, player skill levels, budget constraints, and any regulatory requirements when determining appropriate quality standards for your specific applications.

What are the typical lead times for large baseball orders

Standard lead times for bulk baseball orders range from 2-6 weeks depending on quantity, customization requirements, and supplier inventory levels. Custom printing or specific certification requirements may extend delivery timeframes to 8-12 weeks. Seasonal demand fluctuations can affect availability, with spring orders often requiring longer lead times due to increased demand from educational and recreational facilities preparing for baseball season.

How can buyers verify the authenticity and quality of bulk baseball suppliers

Reputable suppliers should provide detailed product specifications, certification documentation, and references from similar organizations. Request samples before placing large orders and verify that suppliers maintain appropriate business licenses and insurance coverage. Industry associations and trade organizations often maintain directories of approved vendors, while online reviews and testimonials from other institutional buyers provide valuable insights into supplier reliability and product quality.